Water Eater®

Why the Water Eater® Wastewater Evaporator?

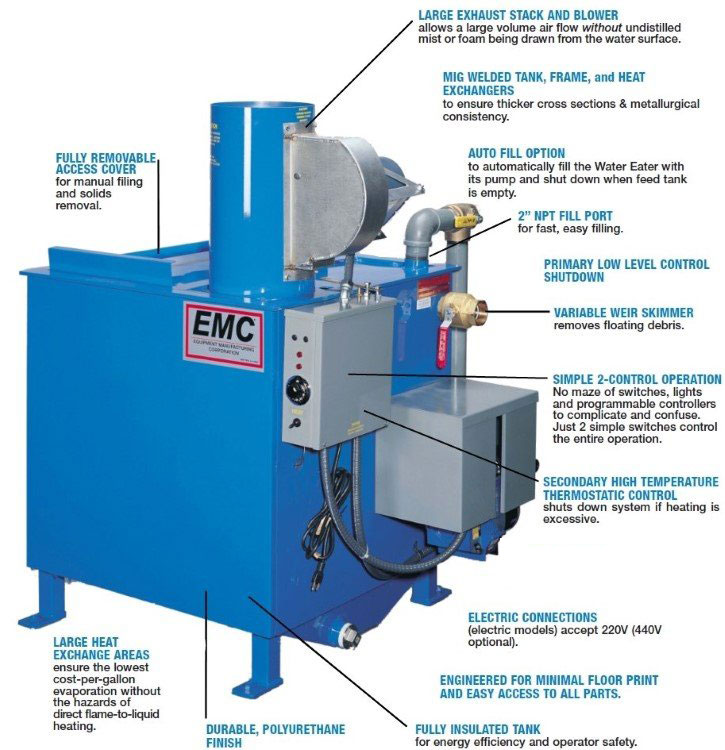

Evaporation is the simplest and most cost effective method for minimizing a wide variety of industrial water-based waste streams. It has been approved by many regulatory agencies around the country as a safe and accepted method for on-site wastewater minimization. EMC®, with the experience gained from over 20 years of manufacturing experience and thousands of systems in the field, is the industry leader in providing high value, reliable, and easy-to-operate wastewater evaporators. All EMC® Water Eaters come with the following standard features.

HEAVY DUTY CONSTRUCTION

The harsh environment inside a wastewater evaporator requires that only heavy gauge materials be used. All tanks (Carbon and 316L Stainless Steel) are of MIG welded, 12 gauge steel construction (316L Stainless steel units also have covers, lid, and vent stack of stainless steel). The top tank frame, which provides rigidity and support, is of solid 3/8" steel plate. The electrically heated Model 85E also has a 3/8" solid steel plate floor/heat exchanger. All exterior sheet metal is 16 gauge painted steel.

EASE OF CLEANOUT

The largest operating cost of a water evaporator (which other evaporator manufacturers do not like to discuss) is the maintenance time required to clean the sludge and/or concentrate from the system. Being well aware of this from our many years of manufacturing experience, ease of cleanout was a primary concern in the design. To minimize cleanout time, a fully removable cover is provided that allows for complete access to the entire tank. Next, most Water Eaters have a low top frame height which allows easy access

without the need for footstools or stands. The electric units, have an obstruction free floor with a 2" step down drain port for draining free flowing fluids.

SAFETY SHUTDOWNS

All Water Eater® water evaporators have redundant shutdown systems. The primary shutdown is a low level displacement switch that deactivates the heating system when the fluid level reaches a point just above the heat exchanger surface. The secondary shutdown is a thermostat controlled sensor that measures the temperature of the heat exchanger surface and/or water temperature.

ENERGY EFFICIENCY

As the volume of wastewater increases, the energy costs of evaporation rise accordingly. Of course, all of our water evaporator tanks are fully insulated to further increase the efficiency and safety of the system.

SPARE PARTS

Wherever possible, industry standardized, off the shelf components are used. A conscious effort is made to utilize parts that can be purchased through local industrial supply houses such as Grainger or McMaster Carr. Your company is not held hostage by the high mark up "captive" parts that can only be purchased from the original equipment manufacturer.

Water Eater® Info